Specialist Cane Sugar Processing Chemicals: Superior Results

Specialist Cane Sugar Processing Chemicals: Superior Results

Blog Article

Release the Possible of Your Workflow With Proven Cane Sugar Handling Chemical Formulas

In the realm of walking stick sugar processing, the mission for operational excellence is a consistent search - Cane Sugar Processing Chemicals. The usage of tested chemical formulas has actually become an important component in maximizing production processes and boosting general performance. By integrating these solutions right into your procedures, a spectrum of advantages awaits, promising improved yields, enhanced pureness degrees, and streamlined procedures that align with your critical goals. As the sector advances, remaining abreast of these innovations could be the setting apart aspect that thrusts your procedures to new elevations of success.

Enhancing Manufacturing Effectiveness

To maximize manufacturing efficiency in walking stick sugar processing, it is necessary to simplify functional procedures and take on ingenious technologies where suitable. By implementing reliable operational treatments, such as automating hand-operated tasks and utilizing data-driven understandings, sugar processing plants can dramatically boost their performance degrees. One key element to concentrate on is the utilization of advanced tracking systems that provide real-time information on numerous phases of the manufacturing process. This makes it possible for fast identification of bottlenecks or ineffectiveness, enabling quick intervention and resolution.

By welcoming automation and digitalization, sugar processing centers can operate with higher accuracy and reliability, inevitably leading to enhanced manufacturing result and enhanced product top quality. In essence, the pursuit of manufacturing efficiency through streamlined processes and innovative technologies is vital for the lasting development and competitiveness of walking cane sugar processing operations.

Making The Most Of Yields and Pureness

Efficiently making best use of yields and keeping high pureness levels are crucial purposes in the walking stick sugar processing sector. Achieving optimal returns while supporting rigid pureness criteria requires a tactical strategy that incorporates sophisticated chemical solutions into the handling process. By using specific chemicals designed to boost removal performance, clarify the juice, and enhance crystallization procedures, sugar mills can dramatically enhance their overall yields and pureness levels.

Improving Process Optimization

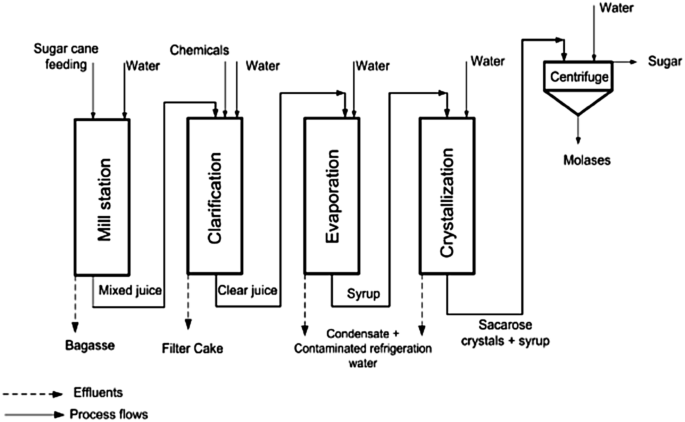

In the realm of walking stick sugar processing, enhancing procedure optimization is paramount for attaining the desired yields and pureness degrees while integrating advanced chemical formulas for boosted efficiency. Process optimization entails fine-tuning different phases of sugar production to optimize output while preserving high top quality. One look at here vital facet of improving process optimization is the mindful calibration of devices such as evaporators, crystallizers, and centrifuges to guarantee they operate at peak effectiveness degrees. In addition, implementing automation and surveillance systems can assist identify bottlenecks or ineffectiveness in real-time, permitting timely modifications to enhance overall performance. Regular upkeep schedules and detailed cleansing treatments also play an essential role in maintaining the processing plant running efficiently and protecting against unanticipated downtime. By continuously reviewing and enhancing each action navigate to these guys of the sugar manufacturing procedure, operators can streamline procedures, decrease energy consumption, decrease waste, and eventually increase profitability. Accepting process optimization as a core principle can bring about sustainable renovations in efficiency and item high quality within the walking stick sugar handling industry.

Getting Operational Goals Properly

With a tactical concentrate on operational quality, the sugar handling market aims to effectively meet its manufacturing targets and quality standards. Achieving functional objectives properly requires a mix of variables such as structured processes, progressed technologies, and enhanced chemical solutions. By making certain that each step of the sugar handling operation is very carefully prepared and implemented, firms can boost performance and efficiency.

One key element of accomplishing functional objectives is the choice of high-grade cane sugar processing chemical formulations. These solutions play a crucial role in different phases of the manufacturing procedure, consisting of extraction, purification, and crystallization. By utilizing tested chemical formulas especially created for walking stick sugar handling, companies can improve yield, reduce handling time, and boost the general high quality of the end product.

Moreover, reliable interaction and partnership among different departments within the organization are crucial for straightening functional goals and making sure smooth workflow - Cane Sugar Processing Chemicals. Regular performance assessments, continuous training programs, and data-driven decision-making processes can further sustain the accomplishment of functional excellence in the sugar handling sector. By executing these strategies, companies can release the full capacity of their procedures and stay ahead in an affordable market

Enhancing Final Product High Quality

Moreover, enhancing end item high quality likewise requires constant surveillance and change of handling criteria to maintain consistency and satisfy high quality requirements. Quality control procedures such as normal screening for pureness, wetness material, and granulation make certain that completion product satisfies industry standards and customer expectations. By buying the right chemical solutions and focusing on quality throughout the manufacturing process, sugar processing centers can accomplish exceptional end product quality that establishes them apart out there.

Verdict

In conclusion, making use of proven walking cane sugar handling chemical solutions can substantially improve production effectiveness, take full advantage of yields and pureness, boost process optimization, accomplish functional goals effectively, and improve final result top quality (Cane Sugar Processing Chemicals). By incorporating these formulations right into procedures, companies can open the complete possibility of their sugar handling centers and make certain a more streamlined and effective production process

Report this page